At what point in European history could a government build a printing press given a basic description?

.everyoneloves__top-leaderboard:empty,.everyoneloves__mid-leaderboard:empty,.everyoneloves__bot-mid-leaderboard:empty{ margin-bottom:0;

}

$begingroup$

Say a time traveler ends up back in time and has earned the good graces of one of the nations' kings by sharing some of his future knowledge. Knowing that the printing press was an important milestone towards increased education and science he suggests the king commit his most skilled people towards trying to create one.

Unfortunately the time traveler did not bring back any documentation on how the printing press was made, nor does he personally know much about the mechanical challenges involved in making one. All he knows is the general idea that removable letters can be locked in place to spell out words, then the machine can be turned by hand to automatically ink and press the letters to paper.

At what point in history would the European world have sufficient mechanization skills to be able to build a functional printing press from this basic idea? In addition how much time, and trial-and-error, would it take for the king's chosen designers to perfect the design of a printing press if given such a general description of a printing press?

For this question ignore any of the 'standard' time traveler problems, like altering history, concerns about language barriers, or being declared a heretic/witch etc. Though if there are concerns that would specifically apply to printing presses, like a belief that a king couldn't be convinced of the value of building one, or some practical reason a functional printing press would not prove as useful under this situation as it did in our own past, I'd be happy to hear about that.

reality-check technological-development time-travel history

$endgroup$

|

show 1 more comment

$begingroup$

Say a time traveler ends up back in time and has earned the good graces of one of the nations' kings by sharing some of his future knowledge. Knowing that the printing press was an important milestone towards increased education and science he suggests the king commit his most skilled people towards trying to create one.

Unfortunately the time traveler did not bring back any documentation on how the printing press was made, nor does he personally know much about the mechanical challenges involved in making one. All he knows is the general idea that removable letters can be locked in place to spell out words, then the machine can be turned by hand to automatically ink and press the letters to paper.

At what point in history would the European world have sufficient mechanization skills to be able to build a functional printing press from this basic idea? In addition how much time, and trial-and-error, would it take for the king's chosen designers to perfect the design of a printing press if given such a general description of a printing press?

For this question ignore any of the 'standard' time traveler problems, like altering history, concerns about language barriers, or being declared a heretic/witch etc. Though if there are concerns that would specifically apply to printing presses, like a belief that a king couldn't be convinced of the value of building one, or some practical reason a functional printing press would not prove as useful under this situation as it did in our own past, I'd be happy to hear about that.

reality-check technological-development time-travel history

$endgroup$

7

$begingroup$

I'm willing to bet the ancient romans could do it, maybe the greek too.

$endgroup$

– Renan

May 24 at 20:49

2

$begingroup$

@Renan If they only have enough paper.

$endgroup$

– user58697

May 25 at 0:10

$begingroup$

The Antekythera mechanism was probably made in 205 BC - but no later than 87 BC. Images & Wikipedia . It knock a moveable type printing press into a cocked hat. Give the people who built it the basic concept and they'd have you printing press by lunchtime. (Or next week, at the latest). FB RusL OGG about to roll trike.jpg

$endgroup$

– Russell McMahon

May 27 at 12:32

$begingroup$

Since you asked about the value on building a printing press to a king, I would argue that telecommunications would be significantly more attractive to a ruler than a printing press. The base concept is incredibly simple and has enormous military potential. Furthermore, the ruling class might not be interested in making literature cheaper as it is responsible for bringing down regimes

$endgroup$

– dexgecko

May 27 at 15:28

$begingroup$

@dexgecko you, I, and the time traveler know that. The King presumably wouldn't know the affect increased availability of literature, and eventually reading, has on the ruling establishment, as the situation has never come up before in his world. And the Time Traveler, who has been raised to respect democracy over monarchy, may 'neglect' to inform the kind of that fact as well ;)

$endgroup$

– dsollen

May 28 at 12:29

|

show 1 more comment

$begingroup$

Say a time traveler ends up back in time and has earned the good graces of one of the nations' kings by sharing some of his future knowledge. Knowing that the printing press was an important milestone towards increased education and science he suggests the king commit his most skilled people towards trying to create one.

Unfortunately the time traveler did not bring back any documentation on how the printing press was made, nor does he personally know much about the mechanical challenges involved in making one. All he knows is the general idea that removable letters can be locked in place to spell out words, then the machine can be turned by hand to automatically ink and press the letters to paper.

At what point in history would the European world have sufficient mechanization skills to be able to build a functional printing press from this basic idea? In addition how much time, and trial-and-error, would it take for the king's chosen designers to perfect the design of a printing press if given such a general description of a printing press?

For this question ignore any of the 'standard' time traveler problems, like altering history, concerns about language barriers, or being declared a heretic/witch etc. Though if there are concerns that would specifically apply to printing presses, like a belief that a king couldn't be convinced of the value of building one, or some practical reason a functional printing press would not prove as useful under this situation as it did in our own past, I'd be happy to hear about that.

reality-check technological-development time-travel history

$endgroup$

Say a time traveler ends up back in time and has earned the good graces of one of the nations' kings by sharing some of his future knowledge. Knowing that the printing press was an important milestone towards increased education and science he suggests the king commit his most skilled people towards trying to create one.

Unfortunately the time traveler did not bring back any documentation on how the printing press was made, nor does he personally know much about the mechanical challenges involved in making one. All he knows is the general idea that removable letters can be locked in place to spell out words, then the machine can be turned by hand to automatically ink and press the letters to paper.

At what point in history would the European world have sufficient mechanization skills to be able to build a functional printing press from this basic idea? In addition how much time, and trial-and-error, would it take for the king's chosen designers to perfect the design of a printing press if given such a general description of a printing press?

For this question ignore any of the 'standard' time traveler problems, like altering history, concerns about language barriers, or being declared a heretic/witch etc. Though if there are concerns that would specifically apply to printing presses, like a belief that a king couldn't be convinced of the value of building one, or some practical reason a functional printing press would not prove as useful under this situation as it did in our own past, I'd be happy to hear about that.

reality-check technological-development time-travel history

reality-check technological-development time-travel history

edited May 24 at 21:18

Cyn

18.4k2 gold badges37 silver badges83 bronze badges

18.4k2 gold badges37 silver badges83 bronze badges

asked May 24 at 20:33

dsollendsollen

20.1k5 gold badges72 silver badges174 bronze badges

20.1k5 gold badges72 silver badges174 bronze badges

7

$begingroup$

I'm willing to bet the ancient romans could do it, maybe the greek too.

$endgroup$

– Renan

May 24 at 20:49

2

$begingroup$

@Renan If they only have enough paper.

$endgroup$

– user58697

May 25 at 0:10

$begingroup$

The Antekythera mechanism was probably made in 205 BC - but no later than 87 BC. Images & Wikipedia . It knock a moveable type printing press into a cocked hat. Give the people who built it the basic concept and they'd have you printing press by lunchtime. (Or next week, at the latest). FB RusL OGG about to roll trike.jpg

$endgroup$

– Russell McMahon

May 27 at 12:32

$begingroup$

Since you asked about the value on building a printing press to a king, I would argue that telecommunications would be significantly more attractive to a ruler than a printing press. The base concept is incredibly simple and has enormous military potential. Furthermore, the ruling class might not be interested in making literature cheaper as it is responsible for bringing down regimes

$endgroup$

– dexgecko

May 27 at 15:28

$begingroup$

@dexgecko you, I, and the time traveler know that. The King presumably wouldn't know the affect increased availability of literature, and eventually reading, has on the ruling establishment, as the situation has never come up before in his world. And the Time Traveler, who has been raised to respect democracy over monarchy, may 'neglect' to inform the kind of that fact as well ;)

$endgroup$

– dsollen

May 28 at 12:29

|

show 1 more comment

7

$begingroup$

I'm willing to bet the ancient romans could do it, maybe the greek too.

$endgroup$

– Renan

May 24 at 20:49

2

$begingroup$

@Renan If they only have enough paper.

$endgroup$

– user58697

May 25 at 0:10

$begingroup$

The Antekythera mechanism was probably made in 205 BC - but no later than 87 BC. Images & Wikipedia . It knock a moveable type printing press into a cocked hat. Give the people who built it the basic concept and they'd have you printing press by lunchtime. (Or next week, at the latest). FB RusL OGG about to roll trike.jpg

$endgroup$

– Russell McMahon

May 27 at 12:32

$begingroup$

Since you asked about the value on building a printing press to a king, I would argue that telecommunications would be significantly more attractive to a ruler than a printing press. The base concept is incredibly simple and has enormous military potential. Furthermore, the ruling class might not be interested in making literature cheaper as it is responsible for bringing down regimes

$endgroup$

– dexgecko

May 27 at 15:28

$begingroup$

@dexgecko you, I, and the time traveler know that. The King presumably wouldn't know the affect increased availability of literature, and eventually reading, has on the ruling establishment, as the situation has never come up before in his world. And the Time Traveler, who has been raised to respect democracy over monarchy, may 'neglect' to inform the kind of that fact as well ;)

$endgroup$

– dsollen

May 28 at 12:29

7

7

$begingroup$

I'm willing to bet the ancient romans could do it, maybe the greek too.

$endgroup$

– Renan

May 24 at 20:49

$begingroup$

I'm willing to bet the ancient romans could do it, maybe the greek too.

$endgroup$

– Renan

May 24 at 20:49

2

2

$begingroup$

@Renan If they only have enough paper.

$endgroup$

– user58697

May 25 at 0:10

$begingroup$

@Renan If they only have enough paper.

$endgroup$

– user58697

May 25 at 0:10

$begingroup$

The Antekythera mechanism was probably made in 205 BC - but no later than 87 BC. Images & Wikipedia . It knock a moveable type printing press into a cocked hat. Give the people who built it the basic concept and they'd have you printing press by lunchtime. (Or next week, at the latest). FB RusL OGG about to roll trike.jpg

$endgroup$

– Russell McMahon

May 27 at 12:32

$begingroup$

The Antekythera mechanism was probably made in 205 BC - but no later than 87 BC. Images & Wikipedia . It knock a moveable type printing press into a cocked hat. Give the people who built it the basic concept and they'd have you printing press by lunchtime. (Or next week, at the latest). FB RusL OGG about to roll trike.jpg

$endgroup$

– Russell McMahon

May 27 at 12:32

$begingroup$

Since you asked about the value on building a printing press to a king, I would argue that telecommunications would be significantly more attractive to a ruler than a printing press. The base concept is incredibly simple and has enormous military potential. Furthermore, the ruling class might not be interested in making literature cheaper as it is responsible for bringing down regimes

$endgroup$

– dexgecko

May 27 at 15:28

$begingroup$

Since you asked about the value on building a printing press to a king, I would argue that telecommunications would be significantly more attractive to a ruler than a printing press. The base concept is incredibly simple and has enormous military potential. Furthermore, the ruling class might not be interested in making literature cheaper as it is responsible for bringing down regimes

$endgroup$

– dexgecko

May 27 at 15:28

$begingroup$

@dexgecko you, I, and the time traveler know that. The King presumably wouldn't know the affect increased availability of literature, and eventually reading, has on the ruling establishment, as the situation has never come up before in his world. And the Time Traveler, who has been raised to respect democracy over monarchy, may 'neglect' to inform the kind of that fact as well ;)

$endgroup$

– dsollen

May 28 at 12:29

$begingroup$

@dexgecko you, I, and the time traveler know that. The King presumably wouldn't know the affect increased availability of literature, and eventually reading, has on the ruling establishment, as the situation has never come up before in his world. And the Time Traveler, who has been raised to respect democracy over monarchy, may 'neglect' to inform the kind of that fact as well ;)

$endgroup$

– dsollen

May 28 at 12:29

|

show 1 more comment

6 Answers

6

active

oldest

votes

$begingroup$

The printing press is not what Gutenberg invented. The printing press itself was known in Europe since the High Middle Ages at least, and in China even earlier. He did not invent movable type, which was also known.

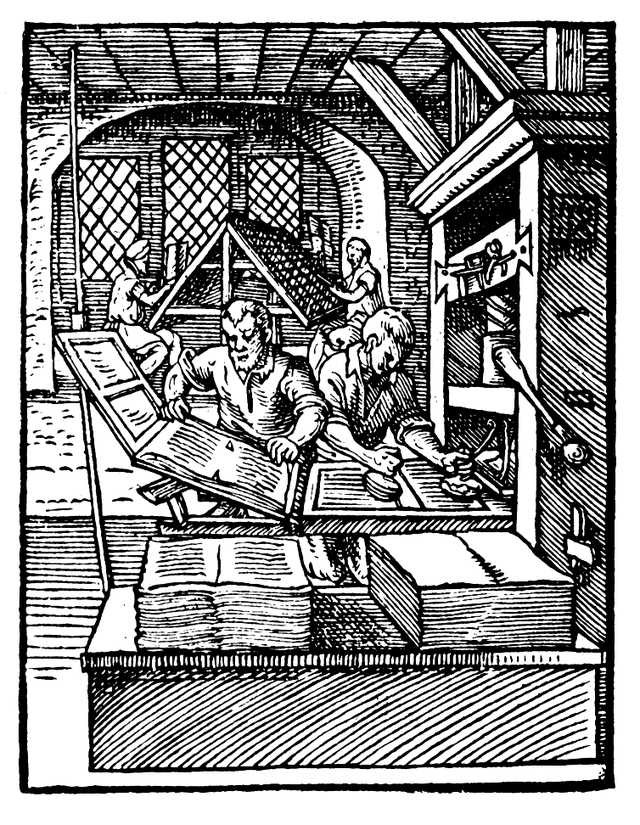

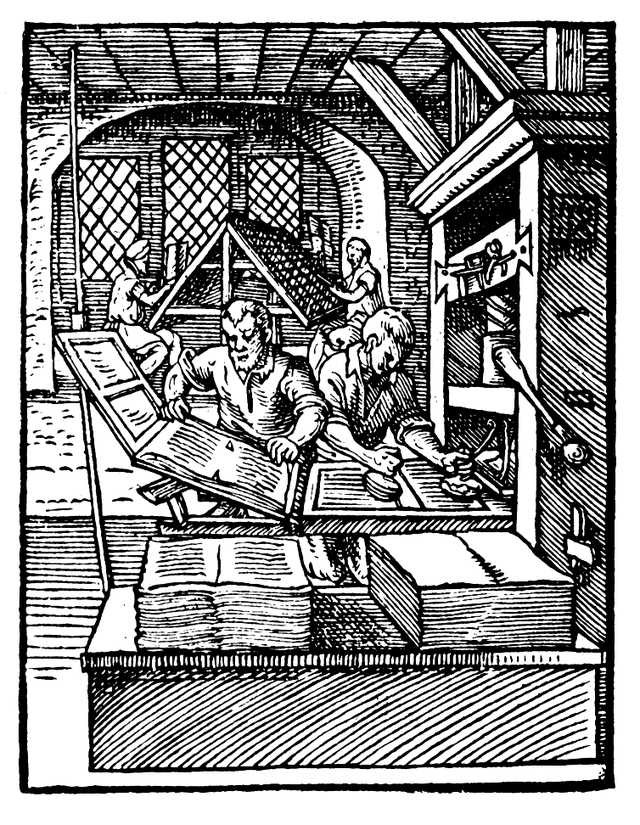

As for the "mechanization skills" needed -- printing was the last of the basic industries to be mechanized. Printing remained extremely labor-intensive up to the very end of the 17th century, and not extremely but still very labor-intensive to the end of the 18th. In the 15th, 16th and most of the 17th century a printing press looked something like this:

A printing shop in 1568. The press is on the right; note that it is a very crude press, with a vertical screw and huge manual winding handles. The man next to the press is applying ink to the printing form. The man next to him has just taken a freshly printed sheet off the form and is examining it and placing it on top of the previously printed sheets. Picture from the 16th century, available on Wikimedia.

Looking at how a printing press really looked like for the first three centuries of the history of printing, one would have to ask what exactly was the contribution of a jeweller? Glad you asked, because what Gutenberg invented was much more important that the press itself (which was already in use) and the idea of movable type (which had come and gone many times).

He invented the hand mould, a simple yet crafty device used for making typographic letters (which are called "sorts" in typographic language).

You see, the basic issue with the idea of printing with movable type was that the printer had to make many many As, many many Bs (but only about 1/10 as many as As), many many Cs and so on. As long as each letter had to be made individually this was basically so labor-intensive as to be uneconomical.

Gutenberg, a jeweller by trade, came up with the following idea:

Make one hard-steel letter punch or master letter of each sort: one uppercase A, one lowercase a, one B, one b and so on. Repeat for each type size you need. This is done by very highly skilled people, usually with jeweller training.

To make a batch of type (type was usually sold by weight, say 10 pounds of type, containing an empirically-determined mix of letters), use the hand mould. The hand mould is a rectangular steel tube, one end of which can be stopped with a replaceable mild steel block; take the master letter in hard steel, put it in the tube and give it a whack with a hammer: it will leave an exact negative impression on the mild steel stopper. This is called the matrix.

Once the matrix (negative impression) has been made, melt a suitable amount of printer's alloy (an alloy of lead, antimony and tin, also invented by Gutenberg) and pour it in the tube; you will get a copy of the letter. Repeat and repeat and repeat until you have the desired amount of letters. Each of the sorts produced by this process looks like this:

Diagram of a cast metal sort. Public domain picture from Wikipedia.

One may want to notice that this is a very very manual process. Printing in general remained a very very manual process up to the end of the 18th century, and was not truly automated until the end of the 19th. See the brief and not entirely misleading Wikipedia articles on movable type and the history of Western typography.

The conclusion is that printing presses with movable type could be built any time since the end of the antiquity; all they really needed was:

Paper (because while printing on vellum is technically possible, and it is actually done for real, the cost of vellum would have been prohibitive);

Access to lead, antimony and tin (availble since the antiquity); and

Access to small amounts of hard steel (available for import from India through Damascus since the late antiquity).

$endgroup$

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

|

show 11 more comments

$begingroup$

I'm going to argue that the cultural aspects don't matter.

Well they matter some. Books (or written pages) and literacy need to exist. But we're talking about a king here. If he decides to humor the funny man from the future, he doesn't need a reason (and whether or not he does so is a story problem, not a Worldbuilding problem). He just needs the funds, workpower, materials, and underlying technology.

Let's assume that the king has available to him sufficient funds and skilled workers of all kinds. That's a pretty reasonable assumption for any kingdom not in crisis.

So what materials and tech do we need and when in European history did they exist?

Paper

While you can have books made out of vellum (animal skin), a printing press works on paper. Vellum (or a less fine parchment) I suppose is possible (especially for a rich kingdom) but paper really is the way to go.

Paper made out of plant like fibres was invented by the Chinese Cai

Lun, who in 105 AD mixed textile fibres and fibres from the bark of

the mulberry in water and produced sheets of paper from that. The

invention of paper was one of the reasons of the successes of early

China, through easier governing of the country. Archeological findings

have shown that paper made from plantlike fibres, were already used

from 140 to 87 BC. (ref)

That doesn't help us though. The question is specific to Europe and Europe and China weren't trading at that point.

The art of papermaking was first exported from China to Korea and

Japan around 610 AD. Arabic people have learned the papermaking

technique in the 8th century from Chinese, as is being told, from

Chinese people skilled in papermaking who were captured. The Arabic

people spread the knowledge during their military campaigns in the

North of Africa and the South of Europe. The first paper manufacturing

in Europe started in 1144 in Xativa (near Valencia) in Spain. The

first papermaking in countries in Europe, which were not controlled by

the Arabians, was in the 13th century in Italy and Spain, although the

usage of paper was already known in Europe since about 1100. A paper

mill in Fabriano (near Ascona) in Italy existed in 1276 (and still

exists nowadays). Around this time sizing paper with animal glue was

invented in Italy. The Germans had their first paper mill in 1389,

followed by the rest of Europe at the end of the 15th century. In

Belgium the first paper production was in Huy (Hoei) in 1405 and in

Holland in in Dordrecht in 1586.

So now it depends on where in Europe you are. If you're in a location with a paper mill, then it's easy. If you're somewhere that has regular trade with a paper mill location, that's also fine. Certainly trade routes were well established by the early Medieval era, but there were other trade routes as early as the 16th century BCE.

So let's assume that the king could acquire enough paper for these needs by the 12th century (paper mill in Spain) and maybe a bit earlier since he'll know to ask for it. Can the kingdom manufacture paper? Maybe. It's a bit more complicated than it seems so someone who doesn't know how might not be of much help. But with some trial and error, it's doable. Certainly by the start of the Roman era and probably sooner.

Ink

This one is easier.

The first man-made ink appeared in Egypt about 4,500 years ago and was

made from animal or vegetable charcoal (lampblack) mixed with glue.

(ref)

Ancient Rome had ink, Medieval Europe had ink (starting about 800 CE). So getting or even inventing a basic ink is pretty straightforward. Except...

In the 15th century, a new type of ink had to be developed in Europe

for the printing press by Johannes Gutenberg...Gutenberg's dye was

indelible, oil-based, and made from the soot of lamps (lamp-black)

mixed with varnish and egg white. Two types of ink were prevalent

at the time: the Greek and Roman writing ink (soot, glue, and water)

and the 12th century variety composed of ferrous sulfate, gall, gum,

and water. Neither of these handwriting inks could adhere to

printing surfaces without creating blurs. Eventually an oily,

varnish-like ink made of soot, turpentine, and walnut oil was created

specifically for the printing press. (ref)

This makes the printing task much harder. Our time traveler probably hasn't a clue about different kinds of ink, let alone how to make them. Maybe trial and error from skilled chemists, alchemists, or other material science types of workers, will do the trick. Maybe not. The ingredients aren't hard to find; the problem is the recipe.

Does this kill our timeline? Perhaps not. The question is about creating a printing press. Not successfully using one.

Fine metalworking

We need tiny type (they can be "large print" but that's still pretty small) made perfectly square. The upraised letters themselves have to be perfectly smooth and flat, with the rest of the metal type so uniform that they all fit together just so. And so they can be held fast with a frame such that none of them slip.

Around 1450, Johannes Gutenberg introduced the metal movable-type

printing press in Europe, along with innovations in casting the type

based on a matrix and hand mould. The small number of alphabetic

characters needed for European languages was an important factor.6

Gutenberg was the first to create his type pieces from an alloy of

lead, tin, and antimony—and these materials remained standard for 550

years. (ref)

The first moveable type printer (porcelain) comes from China in 1040 CE. The first metal one is from Korea in 1377. So this technology is not very old. Even wooden moveable type is from China in 1040. It just doesn't go back that far.

Stone molds for metalworking were around as early as 3000 BCE. And better casting arrived in Egypt not long after. Ancient Egyptians were making metal wire, including ones fine enough to weave into cloth, in the second millennium BCE, along with many other advanced techniques, including alloys that would work for printing.

The first iron working in Europe though was Ancient Greece in the late 10th century BCE. It took until the 8th century BCE to bring ironworking to Central Europe. And until 500 BCE for it to become common in Northern Europe, including Britain.

While bronze working began in Europe in the early 3000's BCE, it took a thousand years or more to spread outside of the Mediterranean. Mostly it was used for weapons and tools and not for very fine work like would be needed for type.

I think this is your sticking point. Yes, there was some fine metalworking available in Ancient times, even many centuries before the common era. But it was not consistent in the way we need.

To get type before the Medieval era or so, the king would have to send someone to an area that could make the type, who would stay for the months necessary to oversee the project.

The machine itself

Eh. This is the easy part. Wood, some basic metal. It's a press. Presses are old hat. It just has to be made very carefully so it fits together just so.

A perfectly flat surface with grooves or markings for the paper to fit. A hand roller to apply ink to the type after it's been fitted into the frame and attached to the machine.

A press mechanism to bring the type frame down on the paper. Done.

Conclusion

I'm going to put this about 1000 years before the common era.

The metalwork is the hardest part. It will likely be outsourced to Greece. But a set of several hundred letters, blanks, numbers, punctuation, etc, should last for many years. So who cares if it takes 2 years to acquire?

In that time, they'll get a source of paper and find an ink recipe that doesn't smear. Building the frame should take a few months and can't really be completed until the type arrives, since it must fit exactly.

Maybe a total of 3 years after the king says "sure, why the hell not?"

$endgroup$

1

$begingroup$

The letters do not need to be that precise as long as they are the same height, type used a interlock not friction, so the sides do not need to be perfectly square.

$endgroup$

– John

May 27 at 14:26

$begingroup$

@John If you have experience with it I'll take your word for it. My best guess is that, if the type letters were not square, they would 1) distort the straight lines of the text (horizontally and/or vertically) and 2) have a risk of coming loose during the printing process (ruining hours of typesetting work).

$endgroup$

– Cyn

May 27 at 17:48

$begingroup$

@Cyn wonky text may be a sacrifice worth making, if only to get your "invention" off the ground. (is there a work for a reverse-engineering of remembered technologies, or reinvention by time travellers? there should be).

$endgroup$

– Starfish Prime

May 27 at 18:49

$begingroup$

@StarfishPrime If you can make your type perfectly flat and even on top, you can make the stem square. The former is a lot harder than the latter IMHO. But they both can be done with molds. How or why could you get perfect tops yet somehow not have the mold make square stems?

$endgroup$

– Cyn

May 27 at 19:44

1

$begingroup$

Fair enough ;-)

$endgroup$

– Starfish Prime

May 27 at 21:11

add a comment |

$begingroup$

Simple (but probably wrong) answer: about the same time as the Antikythera Mechanism.

Simple (but definitely unhelpful) answer: early to mid 1400s.

Long answer:

I'd argue that the printing press isn't the critical thing.

Moveable type dates back to 1800BCE on Crete, as demonstrated by the Phaestos Disk. Block printing existed in China before the 8th century CE, and screw-presses existed in Asia and Europe for a good hundred years before Gutenberg made his particular contribution.

It isn't clear when complex mechanical devcices could first be made, but the Antikythera Mechanism is a pretty fancy bit of gear, and appears somewhere aroud the first century BCE.

The problem is one of motivation. Your question shouldn't be "who could build a printing press" but rather "when would people be prepared to make printing presses to disseminate knowledge and educate the masses", because that's a whole other kettle of fish. Those ancient kings you're trying to pitch to? They'd probably wonder why on earth a peasant needed to know about mathematics and logic, cos it ain't gonna do much for their day to day lives.

I'd be looking at persuading the church, not the state. Christian monasteries had things like Scriptoria from ~500CE, where monks would copy books allowing knowledge to be (slightly) more reliably maintained and disseminated (even if it was largely for missionary purposes at the time). From my highly uneducated point of view, it looks like a monk named Cassiodorus popularised the idea of copying books, and his important work Institutiones which included discussion on the subject was finished around 550 or so. The poor schmucks who actually had to do the grunt work of copying would probably have killed for a mechanised way of doing so. The Carolingian Renaissance and formation of the Holy Roman Empire is probably when this sort of thing really took off, and that wasn't until the late 700s.

Secular (you could probably also describe them as "professional") scribe services appeared not long before Gutenberg's press (relatively speaking), and this isn't a coincidence. Also, around the same era, you get Medieval Universities. Again, not a coincidence.

The printing press facilitated a change, but the environment in which it appeared was already ripe for that change. Without that huge social and cultural foundation, it simply wouldn't have had the impact it did. This is a similar problem to all the other time-travel-technology questions; stuff never arose in a vacuum!

$endgroup$

4

$begingroup$

About those secular scribes which appeared in not long before Gutenberg... In the classical antiquity they had professional publishing houses which put out relatively large editions of popular works (think the Odyssey, or Pliny's Natural History); for this purpose they used teams of dozens of scribes who received dictation. In this way the publishing house could put out a massive one hundred copies of a new volume of Tacitus or Cicero or whatever. The dark Middle Ages came later.

$endgroup$

– AlexP

May 25 at 1:52

$begingroup$

The church is not going to like it either, if peasants could read the bible on their own then they were less reliant on priests. And worse might disagree with the official interpretation.

$endgroup$

– John

May 27 at 14:28

$begingroup$

@John it probably isn't a good idea to sell it as a way of educating the masses to start with, but the church would certainly see it as valuable for their own goals in the near term and once the use of mechanised printing becomes standard expanding the range of publishing might be practical, or setting up clandestine presses for other purposes. Ironically, some of the earliest illegal printing in Europe were religious texts for the Calvinists.

$endgroup$

– Starfish Prime

May 27 at 18:47

add a comment |

$begingroup$

The prerequisites (printing press, movable type, metal casting, paper) were available in some form since antiquity. The enabling factor was most likely cultural: simple European alphabet and existence of critical mass of literate population (not only nobility, clergy and monks, but also townspeople).

$endgroup$

add a comment |

$begingroup$

Essentially, a printing press is a fancy set of stamps. Stamps have been in use since the 4th century, and printing was used in 8th century China already. More likely, the king would ask "Why would we want books and knowledge to be easily accessible?"

$endgroup$

4

$begingroup$

Don't frame it that way: "You Majesty, using this method one can quickly ensure that your laws are known throughout the land!"

$endgroup$

– Keith Morrison

May 24 at 21:51

1

$begingroup$

"So does a steady ruling hand, enforced by the whip and chopping block! It is the only way these simple minded folk truly understand."

$endgroup$

– J Lossner

May 25 at 8:17

$begingroup$

@KeithMorrison except it really doesn't since most peasants could not read. and changes to laws would have to be carried by messengers anyway.

$endgroup$

– John

May 27 at 14:30

add a comment |

$begingroup$

The Antikythera mechanism was probably made in 205 BC - but no later than 87 BC.

Images &

Wikipedia article.

- Wikipedia: "It is a complex clockwork mechanism composed of at least 30 meshing bronze gears. ... Detailed imaging of the mechanism suggests that it had 37 gear wheels enabling it to follow the movements of the Moon and the Sun through the zodiac, to predict eclipses and even to model the irregular orbit of the Moon, where the Moon's velocity is higher in its perigee than in its apogee. This motion was studied in the 2nd century BC by astronomer Hipparchus of Rhodes, and it is speculated that he may have been consulted in the machine's construction.

It 'knocks a movable type printing press into a cocked hat'.

Give the people who built it the basic concept and you'd have your printing press by lunchtime.

(Or next week, at the latest). (OK - next year, but you get the idea).

...........Functional model ...................... Operational diagram .......................... The original

$endgroup$

$begingroup$

What is the relationship between the Anticythera mechanism (which is a clockwork calculator) and a printing press? Printing presses did not have any gears whatsoever until well into the 18th century. They were simple presses -- a solid wooden frame with a vertical screw pushing a solid plate unto the printing form. The entire point is that the question is asking about the wrong device -- the printing press is a very simple device, and it was known and used in Europe since the High Middle Ages, if not earlier. Building the press itself is not a problem, and never was a problem.

$endgroup$

– AlexP

May 27 at 12:53

$begingroup$

@AlexP I read your answer in it's entirety before adding my somewhat whimsical contribution. Obviously the antikythera mechanism is not as nearly closely related functionally as Gutenberg's advance. . My point was (and is) that if the question relates to the degree of technological capability required, given simple instructions, as the OP suggests, then people who could build the antikythera mechanism would have no trouble with a printing press, the matrix process for type formation or any other related activity. Which, I think, is the essence of the question, even if its focus is wrong.

$endgroup$

– Russell McMahon

May 27 at 14:13

add a comment |

Your Answer

StackExchange.ready(function() {

var channelOptions = {

tags: "".split(" "),

id: "579"

};

initTagRenderer("".split(" "), "".split(" "), channelOptions);

StackExchange.using("externalEditor", function() {

// Have to fire editor after snippets, if snippets enabled

if (StackExchange.settings.snippets.snippetsEnabled) {

StackExchange.using("snippets", function() {

createEditor();

});

}

else {

createEditor();

}

});

function createEditor() {

StackExchange.prepareEditor({

heartbeatType: 'answer',

autoActivateHeartbeat: false,

convertImagesToLinks: false,

noModals: true,

showLowRepImageUploadWarning: true,

reputationToPostImages: null,

bindNavPrevention: true,

postfix: "",

imageUploader: {

brandingHtml: "Powered by u003ca class="icon-imgur-white" href="https://imgur.com/"u003eu003c/au003e",

contentPolicyHtml: "User contributions licensed under u003ca href="https://creativecommons.org/licenses/by-sa/3.0/"u003ecc by-sa 3.0 with attribution requiredu003c/au003e u003ca href="https://stackoverflow.com/legal/content-policy"u003e(content policy)u003c/au003e",

allowUrls: true

},

noCode: true, onDemand: true,

discardSelector: ".discard-answer"

,immediatelyShowMarkdownHelp:true

});

}

});

Sign up or log in

StackExchange.ready(function () {

StackExchange.helpers.onClickDraftSave('#login-link');

});

Sign up using Google

Sign up using Facebook

Sign up using Email and Password

Post as a guest

Required, but never shown

StackExchange.ready(

function () {

StackExchange.openid.initPostLogin('.new-post-login', 'https%3a%2f%2fworldbuilding.stackexchange.com%2fquestions%2f147713%2fat-what-point-in-european-history-could-a-government-build-a-printing-press-give%23new-answer', 'question_page');

}

);

Post as a guest

Required, but never shown

6 Answers

6

active

oldest

votes

6 Answers

6

active

oldest

votes

active

oldest

votes

active

oldest

votes

$begingroup$

The printing press is not what Gutenberg invented. The printing press itself was known in Europe since the High Middle Ages at least, and in China even earlier. He did not invent movable type, which was also known.

As for the "mechanization skills" needed -- printing was the last of the basic industries to be mechanized. Printing remained extremely labor-intensive up to the very end of the 17th century, and not extremely but still very labor-intensive to the end of the 18th. In the 15th, 16th and most of the 17th century a printing press looked something like this:

A printing shop in 1568. The press is on the right; note that it is a very crude press, with a vertical screw and huge manual winding handles. The man next to the press is applying ink to the printing form. The man next to him has just taken a freshly printed sheet off the form and is examining it and placing it on top of the previously printed sheets. Picture from the 16th century, available on Wikimedia.

Looking at how a printing press really looked like for the first three centuries of the history of printing, one would have to ask what exactly was the contribution of a jeweller? Glad you asked, because what Gutenberg invented was much more important that the press itself (which was already in use) and the idea of movable type (which had come and gone many times).

He invented the hand mould, a simple yet crafty device used for making typographic letters (which are called "sorts" in typographic language).

You see, the basic issue with the idea of printing with movable type was that the printer had to make many many As, many many Bs (but only about 1/10 as many as As), many many Cs and so on. As long as each letter had to be made individually this was basically so labor-intensive as to be uneconomical.

Gutenberg, a jeweller by trade, came up with the following idea:

Make one hard-steel letter punch or master letter of each sort: one uppercase A, one lowercase a, one B, one b and so on. Repeat for each type size you need. This is done by very highly skilled people, usually with jeweller training.

To make a batch of type (type was usually sold by weight, say 10 pounds of type, containing an empirically-determined mix of letters), use the hand mould. The hand mould is a rectangular steel tube, one end of which can be stopped with a replaceable mild steel block; take the master letter in hard steel, put it in the tube and give it a whack with a hammer: it will leave an exact negative impression on the mild steel stopper. This is called the matrix.

Once the matrix (negative impression) has been made, melt a suitable amount of printer's alloy (an alloy of lead, antimony and tin, also invented by Gutenberg) and pour it in the tube; you will get a copy of the letter. Repeat and repeat and repeat until you have the desired amount of letters. Each of the sorts produced by this process looks like this:

Diagram of a cast metal sort. Public domain picture from Wikipedia.

One may want to notice that this is a very very manual process. Printing in general remained a very very manual process up to the end of the 18th century, and was not truly automated until the end of the 19th. See the brief and not entirely misleading Wikipedia articles on movable type and the history of Western typography.

The conclusion is that printing presses with movable type could be built any time since the end of the antiquity; all they really needed was:

Paper (because while printing on vellum is technically possible, and it is actually done for real, the cost of vellum would have been prohibitive);

Access to lead, antimony and tin (availble since the antiquity); and

Access to small amounts of hard steel (available for import from India through Damascus since the late antiquity).

$endgroup$

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

|

show 11 more comments

$begingroup$

The printing press is not what Gutenberg invented. The printing press itself was known in Europe since the High Middle Ages at least, and in China even earlier. He did not invent movable type, which was also known.

As for the "mechanization skills" needed -- printing was the last of the basic industries to be mechanized. Printing remained extremely labor-intensive up to the very end of the 17th century, and not extremely but still very labor-intensive to the end of the 18th. In the 15th, 16th and most of the 17th century a printing press looked something like this:

A printing shop in 1568. The press is on the right; note that it is a very crude press, with a vertical screw and huge manual winding handles. The man next to the press is applying ink to the printing form. The man next to him has just taken a freshly printed sheet off the form and is examining it and placing it on top of the previously printed sheets. Picture from the 16th century, available on Wikimedia.

Looking at how a printing press really looked like for the first three centuries of the history of printing, one would have to ask what exactly was the contribution of a jeweller? Glad you asked, because what Gutenberg invented was much more important that the press itself (which was already in use) and the idea of movable type (which had come and gone many times).

He invented the hand mould, a simple yet crafty device used for making typographic letters (which are called "sorts" in typographic language).

You see, the basic issue with the idea of printing with movable type was that the printer had to make many many As, many many Bs (but only about 1/10 as many as As), many many Cs and so on. As long as each letter had to be made individually this was basically so labor-intensive as to be uneconomical.

Gutenberg, a jeweller by trade, came up with the following idea:

Make one hard-steel letter punch or master letter of each sort: one uppercase A, one lowercase a, one B, one b and so on. Repeat for each type size you need. This is done by very highly skilled people, usually with jeweller training.

To make a batch of type (type was usually sold by weight, say 10 pounds of type, containing an empirically-determined mix of letters), use the hand mould. The hand mould is a rectangular steel tube, one end of which can be stopped with a replaceable mild steel block; take the master letter in hard steel, put it in the tube and give it a whack with a hammer: it will leave an exact negative impression on the mild steel stopper. This is called the matrix.

Once the matrix (negative impression) has been made, melt a suitable amount of printer's alloy (an alloy of lead, antimony and tin, also invented by Gutenberg) and pour it in the tube; you will get a copy of the letter. Repeat and repeat and repeat until you have the desired amount of letters. Each of the sorts produced by this process looks like this:

Diagram of a cast metal sort. Public domain picture from Wikipedia.

One may want to notice that this is a very very manual process. Printing in general remained a very very manual process up to the end of the 18th century, and was not truly automated until the end of the 19th. See the brief and not entirely misleading Wikipedia articles on movable type and the history of Western typography.

The conclusion is that printing presses with movable type could be built any time since the end of the antiquity; all they really needed was:

Paper (because while printing on vellum is technically possible, and it is actually done for real, the cost of vellum would have been prohibitive);

Access to lead, antimony and tin (availble since the antiquity); and

Access to small amounts of hard steel (available for import from India through Damascus since the late antiquity).

$endgroup$

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

|

show 11 more comments

$begingroup$

The printing press is not what Gutenberg invented. The printing press itself was known in Europe since the High Middle Ages at least, and in China even earlier. He did not invent movable type, which was also known.

As for the "mechanization skills" needed -- printing was the last of the basic industries to be mechanized. Printing remained extremely labor-intensive up to the very end of the 17th century, and not extremely but still very labor-intensive to the end of the 18th. In the 15th, 16th and most of the 17th century a printing press looked something like this:

A printing shop in 1568. The press is on the right; note that it is a very crude press, with a vertical screw and huge manual winding handles. The man next to the press is applying ink to the printing form. The man next to him has just taken a freshly printed sheet off the form and is examining it and placing it on top of the previously printed sheets. Picture from the 16th century, available on Wikimedia.

Looking at how a printing press really looked like for the first three centuries of the history of printing, one would have to ask what exactly was the contribution of a jeweller? Glad you asked, because what Gutenberg invented was much more important that the press itself (which was already in use) and the idea of movable type (which had come and gone many times).

He invented the hand mould, a simple yet crafty device used for making typographic letters (which are called "sorts" in typographic language).

You see, the basic issue with the idea of printing with movable type was that the printer had to make many many As, many many Bs (but only about 1/10 as many as As), many many Cs and so on. As long as each letter had to be made individually this was basically so labor-intensive as to be uneconomical.

Gutenberg, a jeweller by trade, came up with the following idea:

Make one hard-steel letter punch or master letter of each sort: one uppercase A, one lowercase a, one B, one b and so on. Repeat for each type size you need. This is done by very highly skilled people, usually with jeweller training.

To make a batch of type (type was usually sold by weight, say 10 pounds of type, containing an empirically-determined mix of letters), use the hand mould. The hand mould is a rectangular steel tube, one end of which can be stopped with a replaceable mild steel block; take the master letter in hard steel, put it in the tube and give it a whack with a hammer: it will leave an exact negative impression on the mild steel stopper. This is called the matrix.

Once the matrix (negative impression) has been made, melt a suitable amount of printer's alloy (an alloy of lead, antimony and tin, also invented by Gutenberg) and pour it in the tube; you will get a copy of the letter. Repeat and repeat and repeat until you have the desired amount of letters. Each of the sorts produced by this process looks like this:

Diagram of a cast metal sort. Public domain picture from Wikipedia.

One may want to notice that this is a very very manual process. Printing in general remained a very very manual process up to the end of the 18th century, and was not truly automated until the end of the 19th. See the brief and not entirely misleading Wikipedia articles on movable type and the history of Western typography.

The conclusion is that printing presses with movable type could be built any time since the end of the antiquity; all they really needed was:

Paper (because while printing on vellum is technically possible, and it is actually done for real, the cost of vellum would have been prohibitive);

Access to lead, antimony and tin (availble since the antiquity); and

Access to small amounts of hard steel (available for import from India through Damascus since the late antiquity).

$endgroup$

The printing press is not what Gutenberg invented. The printing press itself was known in Europe since the High Middle Ages at least, and in China even earlier. He did not invent movable type, which was also known.

As for the "mechanization skills" needed -- printing was the last of the basic industries to be mechanized. Printing remained extremely labor-intensive up to the very end of the 17th century, and not extremely but still very labor-intensive to the end of the 18th. In the 15th, 16th and most of the 17th century a printing press looked something like this:

A printing shop in 1568. The press is on the right; note that it is a very crude press, with a vertical screw and huge manual winding handles. The man next to the press is applying ink to the printing form. The man next to him has just taken a freshly printed sheet off the form and is examining it and placing it on top of the previously printed sheets. Picture from the 16th century, available on Wikimedia.

Looking at how a printing press really looked like for the first three centuries of the history of printing, one would have to ask what exactly was the contribution of a jeweller? Glad you asked, because what Gutenberg invented was much more important that the press itself (which was already in use) and the idea of movable type (which had come and gone many times).

He invented the hand mould, a simple yet crafty device used for making typographic letters (which are called "sorts" in typographic language).

You see, the basic issue with the idea of printing with movable type was that the printer had to make many many As, many many Bs (but only about 1/10 as many as As), many many Cs and so on. As long as each letter had to be made individually this was basically so labor-intensive as to be uneconomical.

Gutenberg, a jeweller by trade, came up with the following idea:

Make one hard-steel letter punch or master letter of each sort: one uppercase A, one lowercase a, one B, one b and so on. Repeat for each type size you need. This is done by very highly skilled people, usually with jeweller training.

To make a batch of type (type was usually sold by weight, say 10 pounds of type, containing an empirically-determined mix of letters), use the hand mould. The hand mould is a rectangular steel tube, one end of which can be stopped with a replaceable mild steel block; take the master letter in hard steel, put it in the tube and give it a whack with a hammer: it will leave an exact negative impression on the mild steel stopper. This is called the matrix.

Once the matrix (negative impression) has been made, melt a suitable amount of printer's alloy (an alloy of lead, antimony and tin, also invented by Gutenberg) and pour it in the tube; you will get a copy of the letter. Repeat and repeat and repeat until you have the desired amount of letters. Each of the sorts produced by this process looks like this:

Diagram of a cast metal sort. Public domain picture from Wikipedia.

One may want to notice that this is a very very manual process. Printing in general remained a very very manual process up to the end of the 18th century, and was not truly automated until the end of the 19th. See the brief and not entirely misleading Wikipedia articles on movable type and the history of Western typography.

The conclusion is that printing presses with movable type could be built any time since the end of the antiquity; all they really needed was:

Paper (because while printing on vellum is technically possible, and it is actually done for real, the cost of vellum would have been prohibitive);

Access to lead, antimony and tin (availble since the antiquity); and

Access to small amounts of hard steel (available for import from India through Damascus since the late antiquity).

edited May 25 at 1:43

answered May 24 at 21:30

AlexPAlexP

45.8k9 gold badges106 silver badges181 bronze badges

45.8k9 gold badges106 silver badges181 bronze badges

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

|

show 11 more comments

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

36

36

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

$begingroup$

+1 for providing useful education on Gutenberg! I think the very fact you had to write this answer should inform everyone how doomed any time traveller is. Knowing about a mechanical printing press absolutely does not automatically include knowing about hand-moulded type. This sort of information should pop up on every time-travelling technologist question!

$endgroup$

– Starfish Prime

May 24 at 21:35

16

16

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

$begingroup$

This is a great example to illustrate a common misconception about technology. The fact that some technologies weren't developed earlier wasn't caused by people being too stupid and not coming to the idea about them sooner. In fact, many did. It's just that it would have been either uneconomical or unreliable to actually build them, given the circumstances, economic situation, and other technologies in that time.

$endgroup$

– vsz

May 25 at 11:40

1

1

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

$begingroup$

@Schmuddi: Printing on textiles was not feasible until very late, well into the modern age. Before the 19th century paper and vellum are the only materials suitable for printing on, I'm afraid. Lead, antimony and tin were available since the antiquity, so they are not a problem. Printer's alloy melts at a low temperature, is much less soft than pure lead, and when melted fills the matrix very well so that is copies the smallest details. My knowledge of metallurgy is much too rudimentary to say whether is can be replaced with something else; what I know is that is was never replaced.

$endgroup$

– AlexP

May 26 at 12:17

4

4

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

$begingroup$

@Schmuddi: And before the modern age textiles were very expensive. Nowadays clothes are dirt cheap, but before the industrial revolution fabric was very very much less affordable. Women spent a lot of their time spinning and weaving, and clothes were still so expensive that they used to be quoted explicitly in inheritances.

$endgroup$

– AlexP

May 26 at 12:19

2

2

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

$begingroup$

@Schmuddi – the matrix is required to allow large quantities of identical type to be made from one set of steel punches, by different shops. So you need 3 qualities of metal – hard steel for the punch, a softer steel for the matrix, and finally the printer's lead. The alloy in question has good properties of a low melting point (making it practical and safe to use and better for the matrix), and good hardness (for printing reliably and durably)

$endgroup$

– Dan W

May 27 at 9:28

|

show 11 more comments

$begingroup$

I'm going to argue that the cultural aspects don't matter.

Well they matter some. Books (or written pages) and literacy need to exist. But we're talking about a king here. If he decides to humor the funny man from the future, he doesn't need a reason (and whether or not he does so is a story problem, not a Worldbuilding problem). He just needs the funds, workpower, materials, and underlying technology.

Let's assume that the king has available to him sufficient funds and skilled workers of all kinds. That's a pretty reasonable assumption for any kingdom not in crisis.

So what materials and tech do we need and when in European history did they exist?

Paper

While you can have books made out of vellum (animal skin), a printing press works on paper. Vellum (or a less fine parchment) I suppose is possible (especially for a rich kingdom) but paper really is the way to go.

Paper made out of plant like fibres was invented by the Chinese Cai

Lun, who in 105 AD mixed textile fibres and fibres from the bark of

the mulberry in water and produced sheets of paper from that. The

invention of paper was one of the reasons of the successes of early

China, through easier governing of the country. Archeological findings

have shown that paper made from plantlike fibres, were already used

from 140 to 87 BC. (ref)

That doesn't help us though. The question is specific to Europe and Europe and China weren't trading at that point.

The art of papermaking was first exported from China to Korea and

Japan around 610 AD. Arabic people have learned the papermaking

technique in the 8th century from Chinese, as is being told, from

Chinese people skilled in papermaking who were captured. The Arabic

people spread the knowledge during their military campaigns in the

North of Africa and the South of Europe. The first paper manufacturing

in Europe started in 1144 in Xativa (near Valencia) in Spain. The

first papermaking in countries in Europe, which were not controlled by

the Arabians, was in the 13th century in Italy and Spain, although the

usage of paper was already known in Europe since about 1100. A paper

mill in Fabriano (near Ascona) in Italy existed in 1276 (and still

exists nowadays). Around this time sizing paper with animal glue was

invented in Italy. The Germans had their first paper mill in 1389,

followed by the rest of Europe at the end of the 15th century. In

Belgium the first paper production was in Huy (Hoei) in 1405 and in

Holland in in Dordrecht in 1586.

So now it depends on where in Europe you are. If you're in a location with a paper mill, then it's easy. If you're somewhere that has regular trade with a paper mill location, that's also fine. Certainly trade routes were well established by the early Medieval era, but there were other trade routes as early as the 16th century BCE.

So let's assume that the king could acquire enough paper for these needs by the 12th century (paper mill in Spain) and maybe a bit earlier since he'll know to ask for it. Can the kingdom manufacture paper? Maybe. It's a bit more complicated than it seems so someone who doesn't know how might not be of much help. But with some trial and error, it's doable. Certainly by the start of the Roman era and probably sooner.

Ink

This one is easier.

The first man-made ink appeared in Egypt about 4,500 years ago and was

made from animal or vegetable charcoal (lampblack) mixed with glue.

(ref)

Ancient Rome had ink, Medieval Europe had ink (starting about 800 CE). So getting or even inventing a basic ink is pretty straightforward. Except...

In the 15th century, a new type of ink had to be developed in Europe

for the printing press by Johannes Gutenberg...Gutenberg's dye was

indelible, oil-based, and made from the soot of lamps (lamp-black)

mixed with varnish and egg white. Two types of ink were prevalent

at the time: the Greek and Roman writing ink (soot, glue, and water)

and the 12th century variety composed of ferrous sulfate, gall, gum,

and water. Neither of these handwriting inks could adhere to

printing surfaces without creating blurs. Eventually an oily,

varnish-like ink made of soot, turpentine, and walnut oil was created

specifically for the printing press. (ref)

This makes the printing task much harder. Our time traveler probably hasn't a clue about different kinds of ink, let alone how to make them. Maybe trial and error from skilled chemists, alchemists, or other material science types of workers, will do the trick. Maybe not. The ingredients aren't hard to find; the problem is the recipe.

Does this kill our timeline? Perhaps not. The question is about creating a printing press. Not successfully using one.

Fine metalworking

We need tiny type (they can be "large print" but that's still pretty small) made perfectly square. The upraised letters themselves have to be perfectly smooth and flat, with the rest of the metal type so uniform that they all fit together just so. And so they can be held fast with a frame such that none of them slip.

Around 1450, Johannes Gutenberg introduced the metal movable-type

printing press in Europe, along with innovations in casting the type

based on a matrix and hand mould. The small number of alphabetic

characters needed for European languages was an important factor.6

Gutenberg was the first to create his type pieces from an alloy of

lead, tin, and antimony—and these materials remained standard for 550

years. (ref)

The first moveable type printer (porcelain) comes from China in 1040 CE. The first metal one is from Korea in 1377. So this technology is not very old. Even wooden moveable type is from China in 1040. It just doesn't go back that far.

Stone molds for metalworking were around as early as 3000 BCE. And better casting arrived in Egypt not long after. Ancient Egyptians were making metal wire, including ones fine enough to weave into cloth, in the second millennium BCE, along with many other advanced techniques, including alloys that would work for printing.

The first iron working in Europe though was Ancient Greece in the late 10th century BCE. It took until the 8th century BCE to bring ironworking to Central Europe. And until 500 BCE for it to become common in Northern Europe, including Britain.